Due to the tool concept, both parts are provided as bulk goods in the conveyor and positioned by means of robots and welded by means of lasers (laser welding technology).

The integral connection guarantees minimal contact resistance as well as consistent quality over the entire life time.

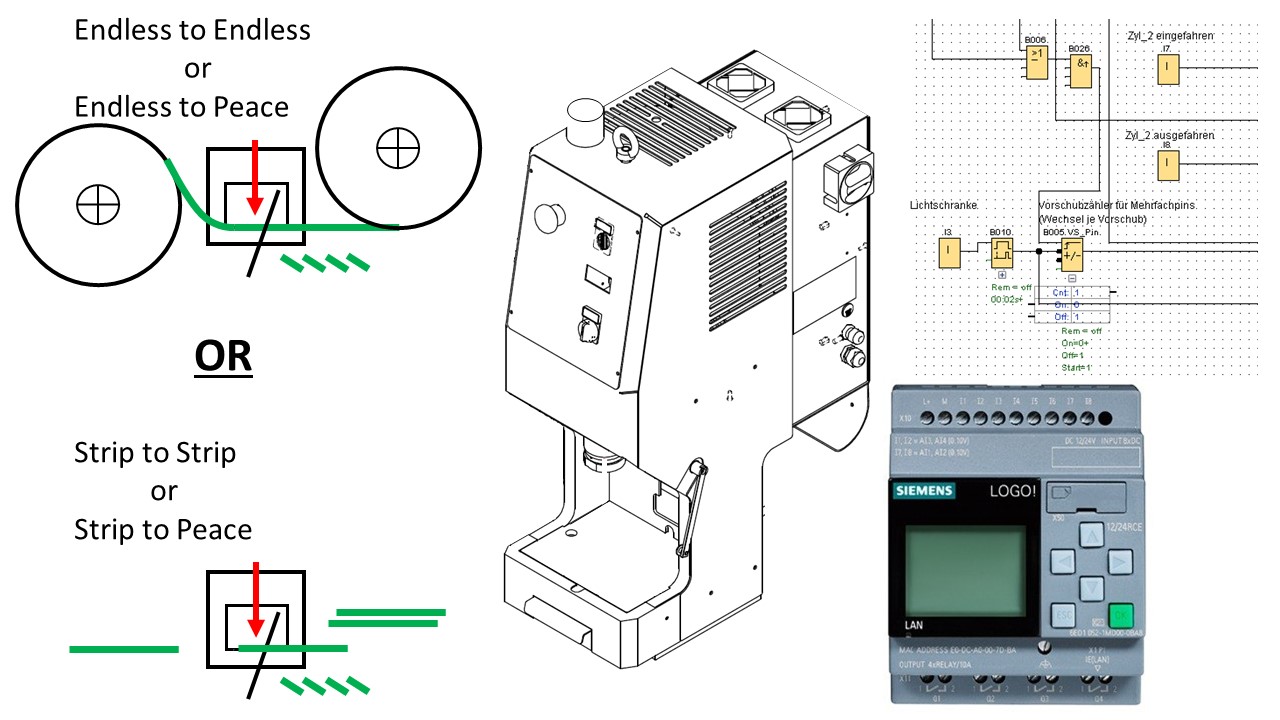

A lack of skilled workers and increasing numbers in the prototype phase have led us to design and build a machine for endless belt and/ or strip sections.

This enables us to produce reliable small batches for our customers.

Laser cut for flexible customer requirements in cutting geometry, stamping and bending technology as in series production.

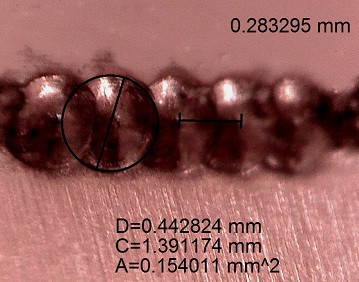

In addition: Everything naturally measured on our KEYENCE IM 6125 including statistical evaluation.

Typically quantities of 5,000 to 500,000 parts/ set per year.

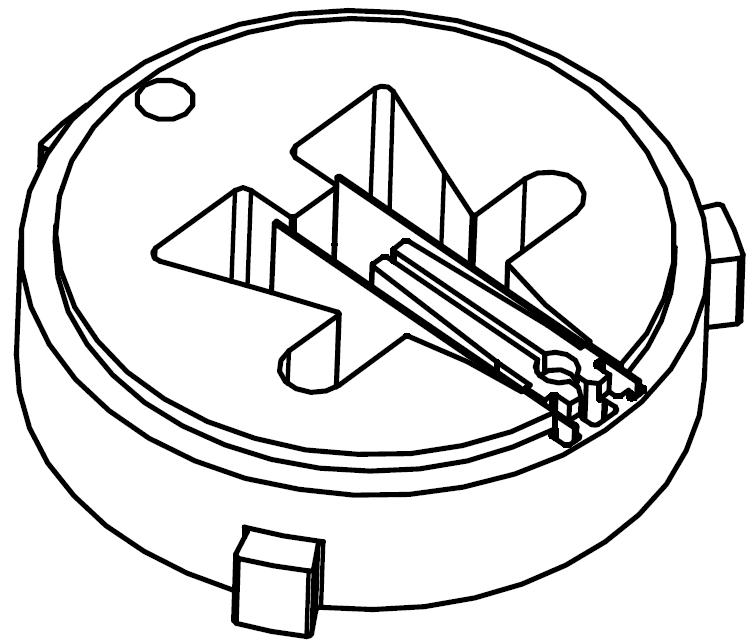

Increasing quality requirements in laser welding technology have prompted us to develop our own CNC laser welding machine.

Follwing: laser welding process of press-fit aeres in customer-specific distances.

Your advantage: No conversion costs for high-precision punching tools are required.

Left: welding including video. Right: CNC machine with XY table:

B-samples:

from prototype (functional sample) to C-sample:

Pitch corrections in stamping part for press fit EloPin pitch from 5,08mm reduced to 4,0mm

Krypton-Fluorid-Excimer-laser (wave-length 248nm), electrical animanted;

Sequence of pictures: primitive state, cleaning 500 and 980 pulses past,

process time 2.8 sec.

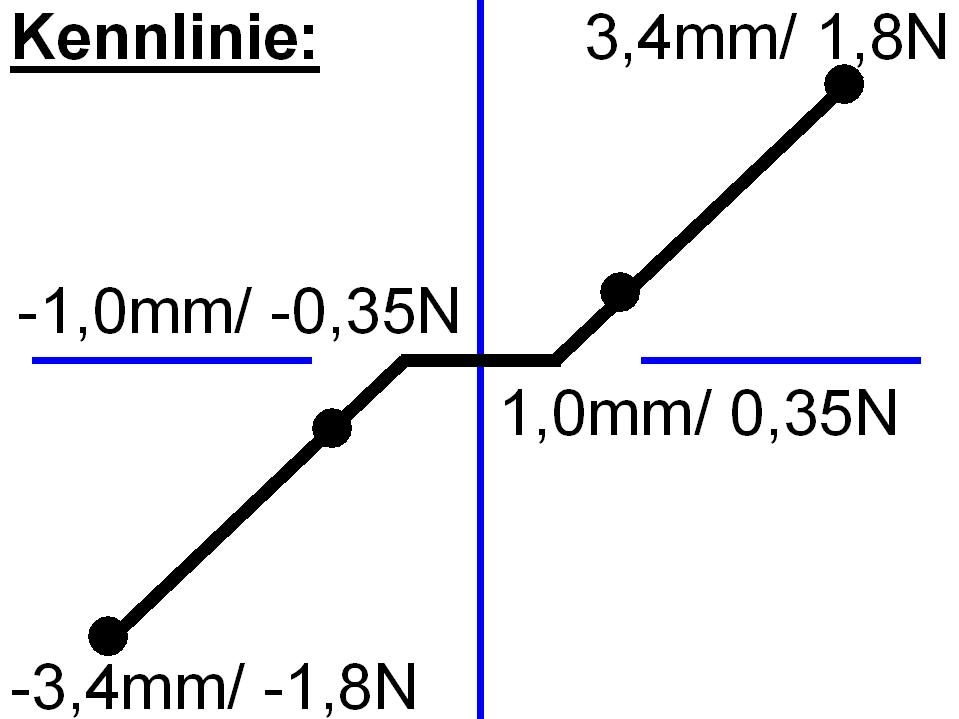

Definition of reference standard in spring characteristic as well as project management until mass-produktion (SOP)

increase in productivity/ to limit consequences of machinery hazard incidents until Run@Rate:

Requirement to the overlapping seam:

no visibility of the seam after surface finishing on outer shape

welding-partners each 1.4301 t=0.3mm

mechaSYS GmbH • Christinstraße 18 • 75177 Pforzheim • Deutschland