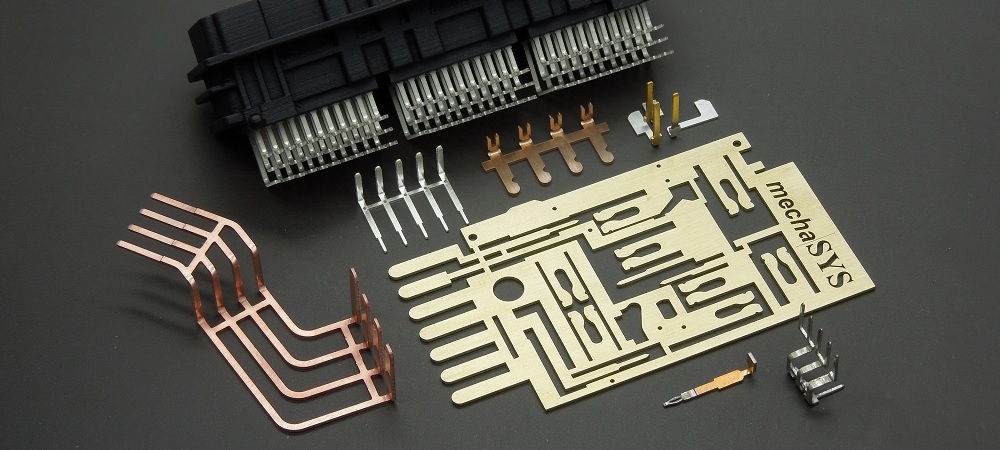

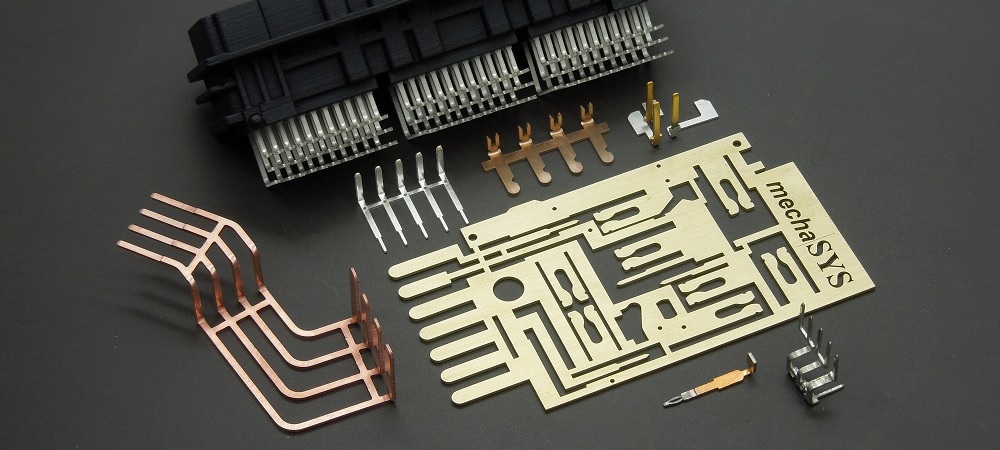

Laser Cutting of Sheet Metal

With laser cutting, we can precisely process all metallic, non-toxic materials in material thicknesses from 0.2 to 2.0 mm.

Highly thermally conductive or reflective metals such as copper or brass can hardly be cut at all with conventional CO2 lasers (wavelength 1600 nm). With our high-precision 1kW fiber laser (Nd: YAG with a wavelength of 1064nm) in combination with highly dynamic linear drives, we can produce your own laser cuts in copper and brass.

Due to our extremely small focus of 0.05mm, we usually create a kerf of 0.07mm, so that the most delicate contours (especially inner contours) can be realized without mechanical stress, as the processing takes place without contact.

This enables high-quality and precise samples, blanks, prototypes and / or small series in contract manufacturing using cutting lasers. - Accuracies of +/- 0.01mm, which are required in the sealing area for plastic encapsulation for complete plugs or housings.

Precision in the laser machining of sheet metal

Our laser systems cuts the sheet more accurately and faster than standard laser systems, which is made possible by the use of linear technology in the drives. Therefore, the machines are also suitable for pure contract work. Thus, the laser offers considerable advantage when especially thin sheets are to be processed.

Materials - each metal:

- Non-ferrous metals (Cu, CuSn0,15, CuSn6, CuZn30, CuZn37, CuNiSi, ...),

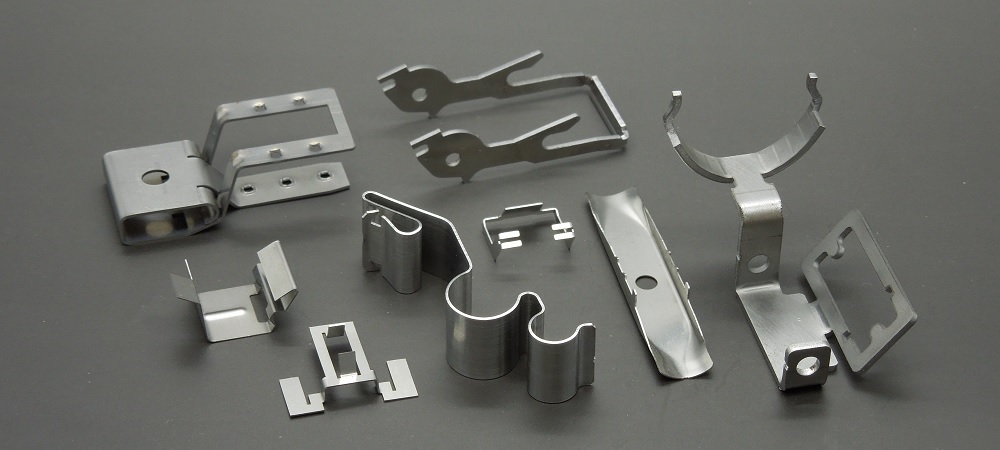

- steel, Hilumin,

- stainless steel (1.4301 = AISI 304, 1.4404 = AISI 316L ...),

- spring steel (1.4310 = AISI 301),

- Titanium,

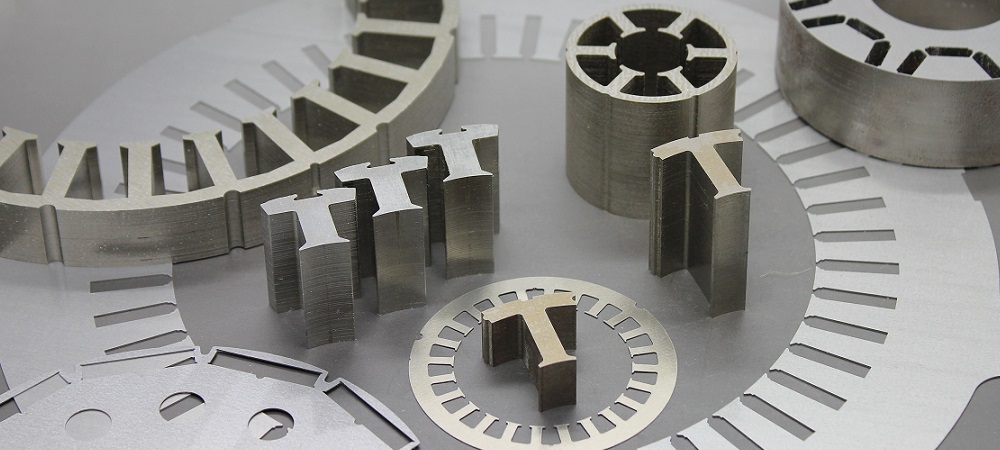

- electrical sheets (M235, M270, NO20, NO30, ...), ...

- No CuBe (Copper-Beryllium alloy) caused by toxic cutting steam.

Dimensions

Sheet thickness from 0.2mm to 2.0mm, max. metal sheets of 1.250mm x 1.250mm

Industry sectors

The laser cutting technology is suitable for applications in almost every industry such as

- Automotive / Automotive

- White goods (household appliances)

- Medical technology

- Electrical engineering

- Precision engineering

- Jewelry and watches, also front panels for DIY Word Clocks

- individual grave slabs out of Copper or Stainless Steel

- other industries

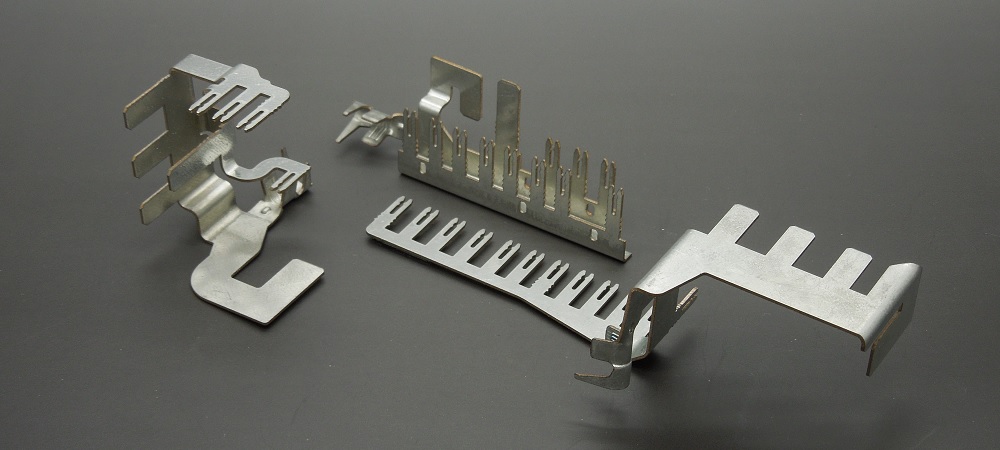

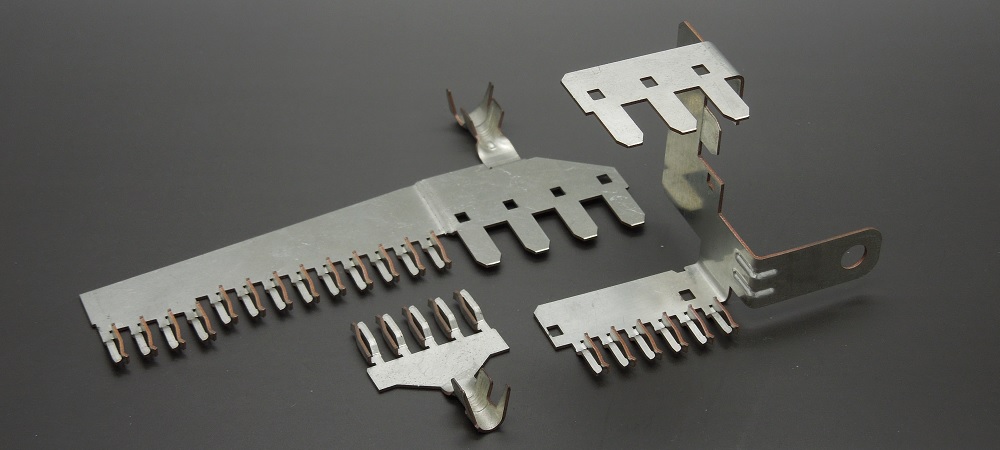

Examples of end products, samples and prototypes