Laser Welding

Laser welding is a very gentle welding technique because the heat input takes place in a locally very limited area. This advantage makes it possible to connect critical components with one another in a materially reliable manner without anealing the material.

In the case of laser welding, the two welding partners are pre-assembled with each other as gap-free as possible in order to subsequently weld them.

The background is that laser welding generally does not use filler material. Exception in hardfacing or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molds in abrasive plastics with glass fiber filling.

Materials - almost all metals:

- • Non-ferrous metals (Cu, CuSn0,15, CuSn6, CuNiSi, ...)

- • titanium,

- • steel, stainless steel (1.4301 = AISI 304, 1.4404 = AISI 316L ...),

- • spring steel (1.4310 = AISI 301),

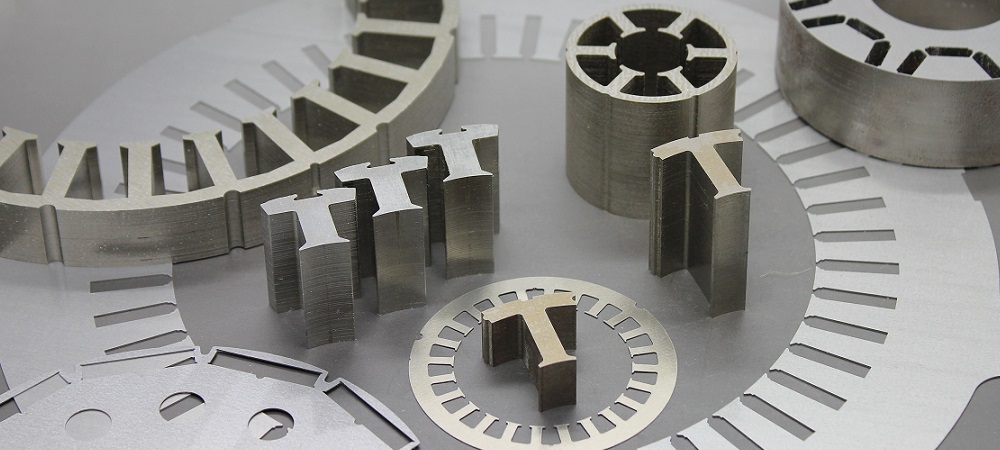

- • electrical sheets (M235, M270, NO20, NO30, ...), ...

- • No CuZn (brass) due to the different melting points of the alloy components of the crystal mixture

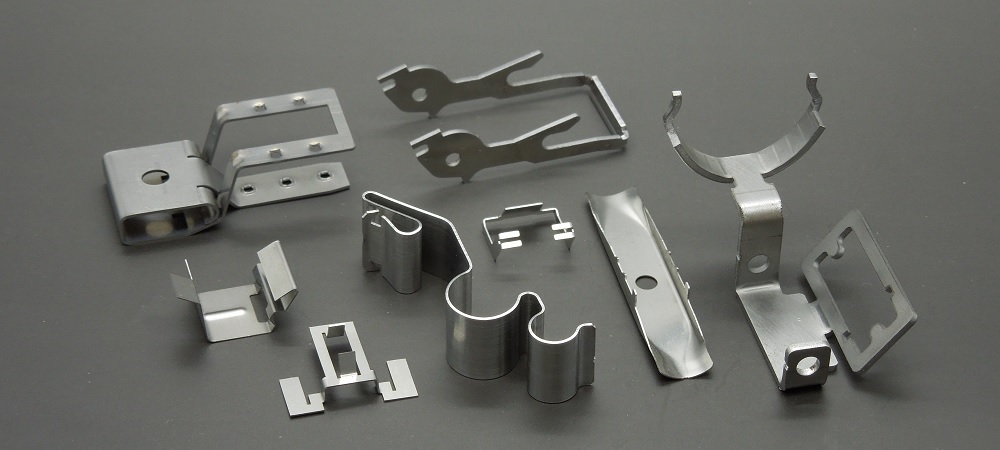

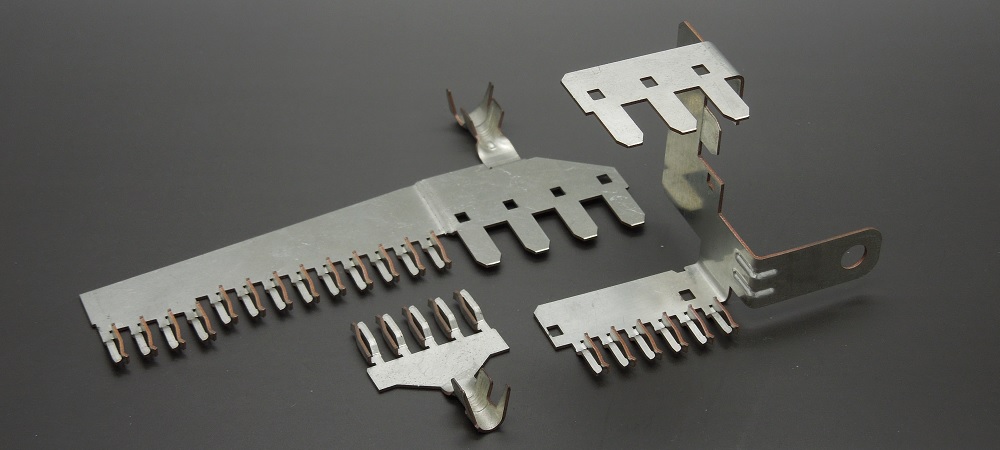

Examples: Laser welding of copper-alloy and stainless steel

|

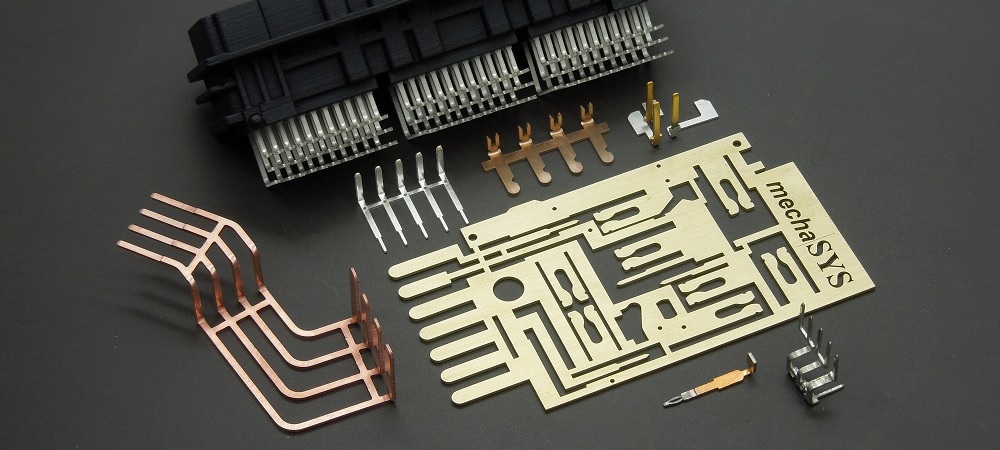

Welding of printed circuit board press-fit technology/ press-fit zones for individual hole spacing in printed circuit board without costly tooling changes in stamping. Process: Laser cutting of the connector with right zone and left gap from pre-punched tape (following EloPin), mounting of the left pin and subsequent laser welding.

|

|

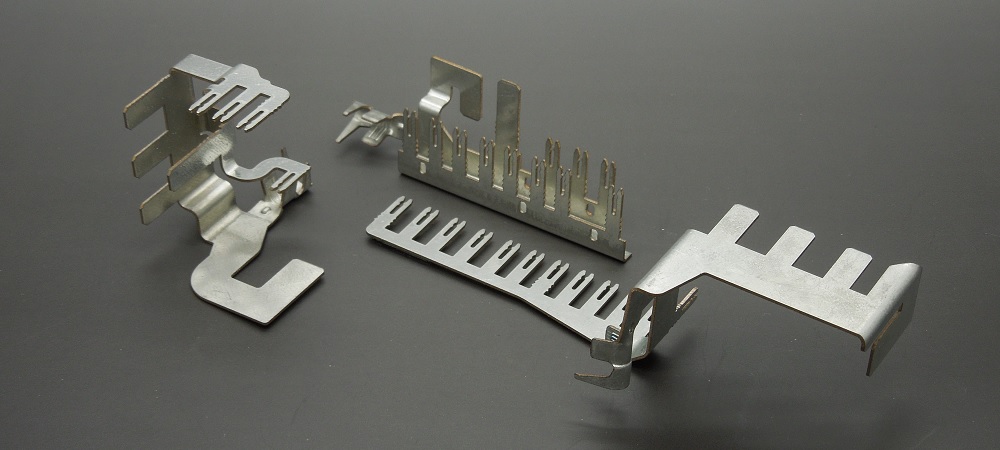

Laserwelding of turned bolt in stamped plate, both out of stainless steel. Argon was used for protection during welding process. |