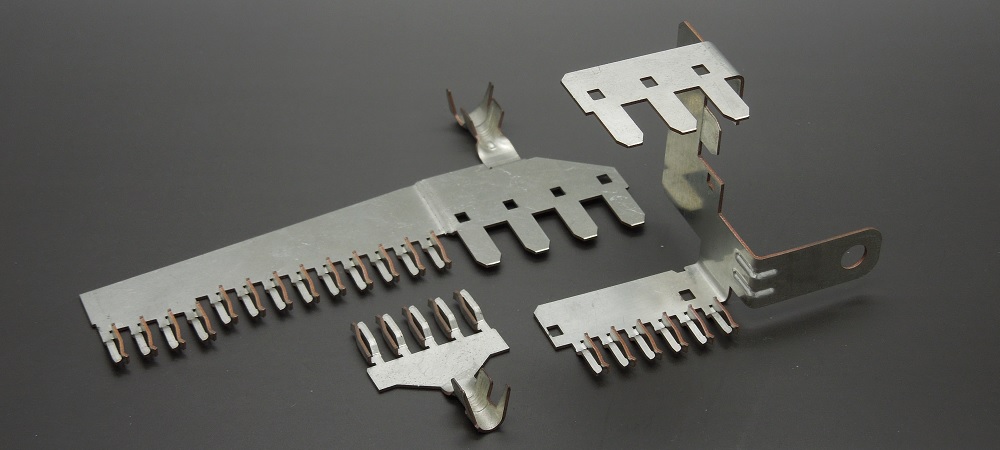

Product Development

We are happy to support our customers in product development and the design of their components and systems with our daily practical relevance.

The question arises again and again

- meaningful, clever solutions,

- Cost cutting,

- Enabling multi-supplier strategy due to widely available raw materials, alloys and plastics, ...

- Integral construction (several functions integrated in one component),

- Substitution of materials,

- resource-saving concepts,

- Avoidance of toxicity in the downstream processes,

- the possibility of later recycling,

- ...

A frequently asked initial question on our part: Why was this material chosen? The answer is often: "Because we did it this way in the previous model."

But mostly something essential has changed. Is it the:

- Installation space,

- possible load changes,

- Ambient temperature,

- Electricity or

- ...?

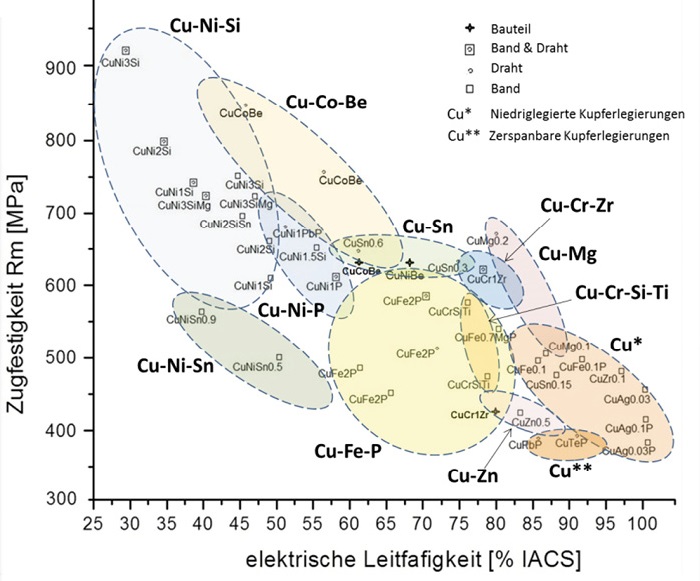

The following overview is intended to help you choose the right material for copper materials and alloys.

Please do not hesitate to contact us.

CAD systems used on our part

Autodesk INVENTOR and

Hexagon VISI

2D:

- DWG

- DXF

3D:

- STEP

- CATPart (Catia)

- bedingt IGES