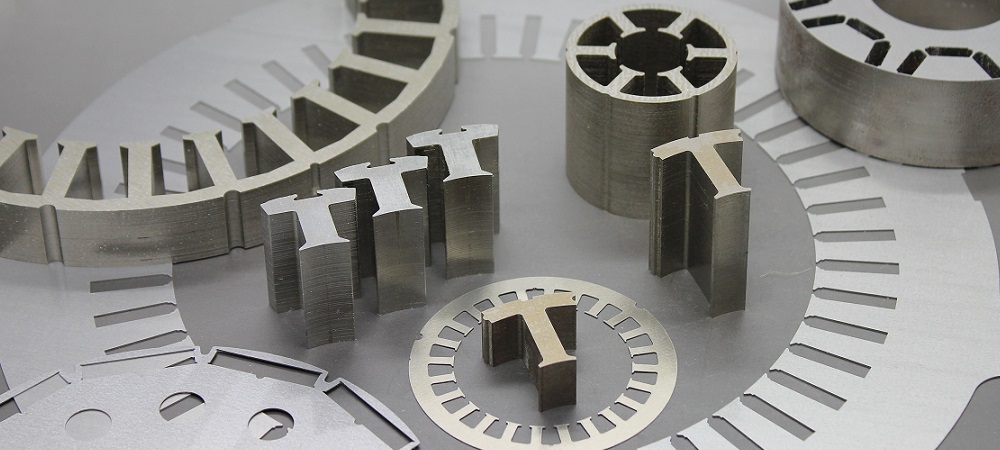

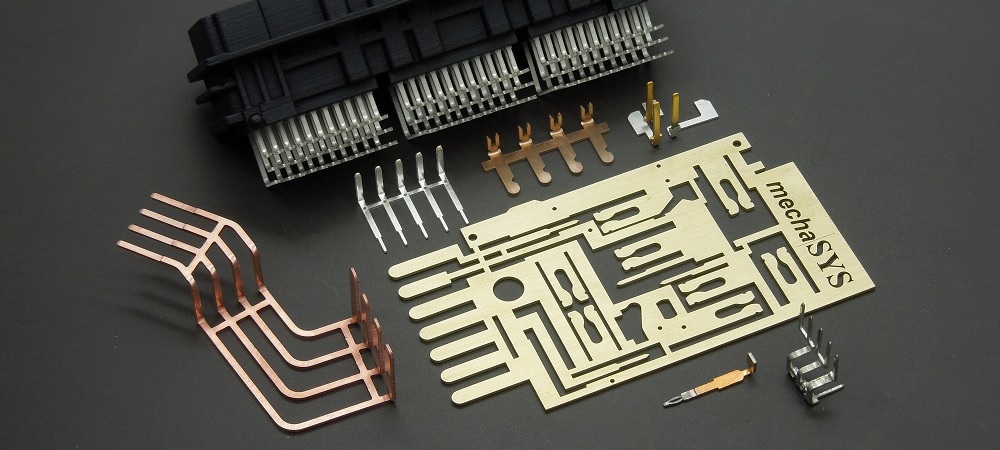

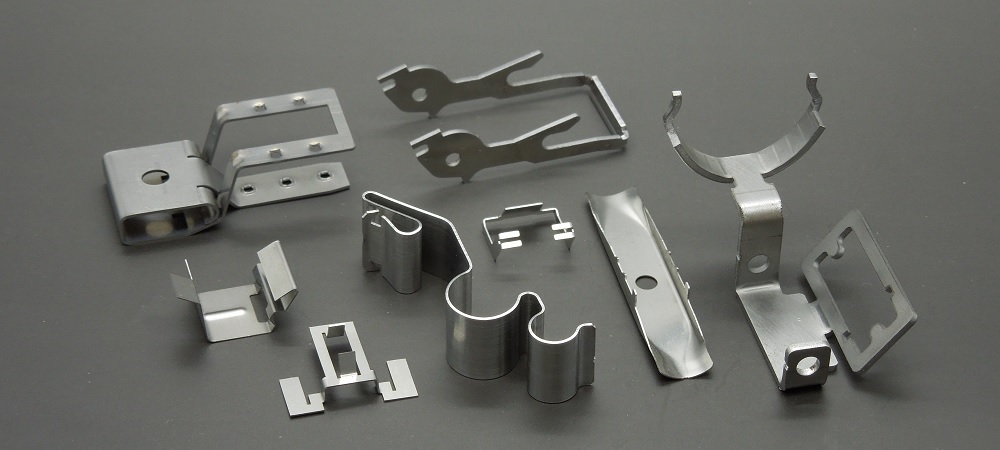

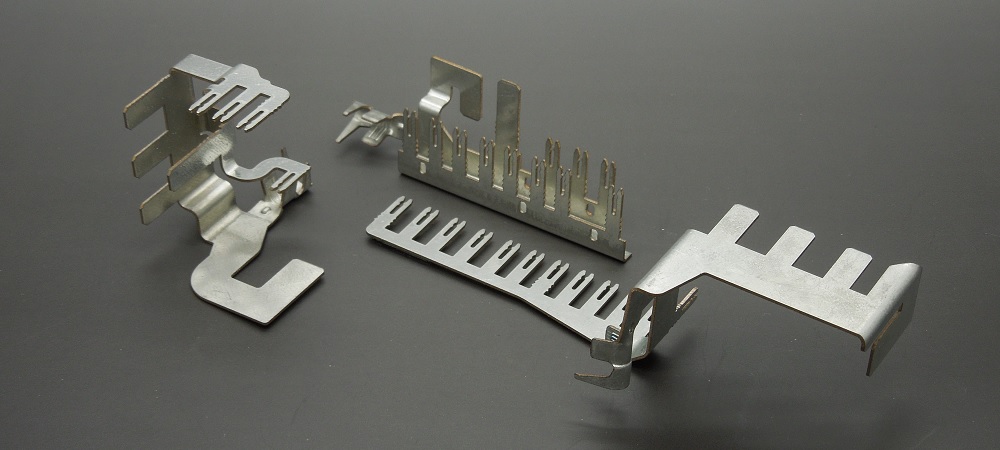

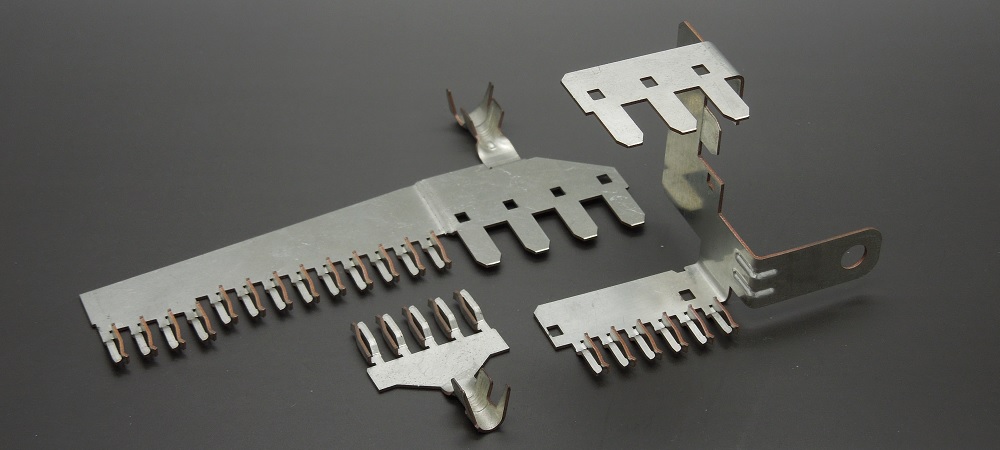

Samples, Prototypes and Smaller Batches out of Sheet Metal

Laser cutting, embossing and bending or punching including electroplating, prototypes and small series - all from one source!

... we made a virtue out of necessity: a holistic concept for your parts.

So we usually produce your individual samples, prototypes and small batches without proportional tool costs.

This makes us very flexible, efficient and cost-effective for small quantities - in extreme cases from quantity 1.

This is made possible by our modular bending system.

All out of one hand:

- different raw material on stock

- lasercutting also out of pre-stamped strips (f.e. pressfit area) by camera on machine) of sheet-metal

- coining, bending, folding, pressing

- stamping of functional areas (area smoothly cut f.e. 60%)

- punching with progressive tool, depending on economic aspects

- assembly (f.e. bolds, rivets, nuts, ...)

- laser engraving/ labeling

- CNC-laserwelding (f.e. PCB-pressfit areas in Cu-alloys, bolts and theads in stainless steel, ...)

- plating complete or partial by partners

Advantage for the customer:

a contact person for your prototypes and the necessary freedom for planning your series - regardless of the industry.

You can find us in almost every branch of industry, e.g. mechatronics, e-mobility, precision engineering and switch technology such as relays, medical technology, apparatus construction, jewelry and clocks, furniture (fittings and hinge technology), ventilation and air conditioning technology ... You haven't found your industry here, talk to us!

Abstract of our Machines:

- Laser cutting and precissoin waterbeam cutting

- Bending: manual in prism for micro parts, CNC bending technology or folding machine for standard parts

max. Bending Length 550mm

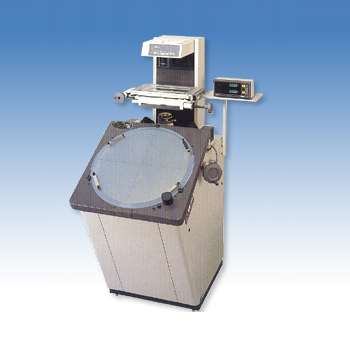

- Quality technology: manuel or programmable measurement technology

Source: Mitutoyo, Keyence

- bigger lot sizes: process stamping

- Coining and bending-

mostly without any tool costs.

Starting from piece number 1 high efficient and economic.

- Plating by partners.

- Assembly:

form-locked: i.e. crimp, tox,...

force-locked: i.e. clip, force fitting, ... or

material-locked: i.e. laser welding, laser soldering, glueing, ...

CAD-System

VISI 3D

Autodesk INVENTOR 3D

Autodesk AUTOCAD 2D - trial version here

possible data-transfer:

2D:

- DWG

- DXF

3D:

- STEP

- CATPart (Catia)

- bedingt IGES